Hot sale high quality mobile aggregate vibrating screen Introduction

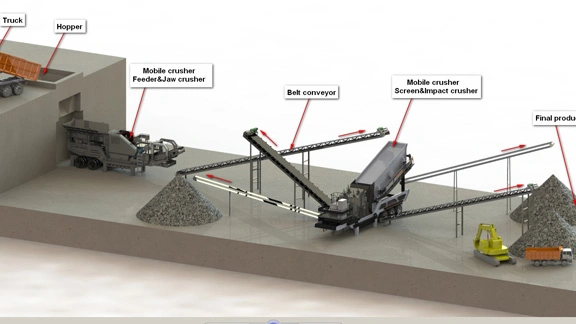

In time of two-stage and three-stage medium and fine crushing, if the K-series portable crushing and screening plants are equipped with the CS, HST or HPT series cone crusher with high performance and high production capacity, we can achieve high productivity, large crushing ratio and excellent grain shape. The CS, HST or HPT series cone crushers are perfectly designed in crushing stroke, crushing speed and crushing chamber shape, which, as proved, has advantages in performance, efficiency, production capacity and product quality over the traditional cone crushers.

When medium and fine cone crushers are needed in the two-stage or three-stage portable crushing process, according to the crushing application requirements, there are several portable plants available for options, including nine types equipped with cone crushers and six types equipped with vertical shaft impact crushers; moreover, such portable plants are equipped with screening machines, able to classify materials or go into next-stage crushing.

The K-series medium and fine crushing and screening portable plants boast the maximum throughput of A + t/h. There are three kinds of pure vibrating screen types available. As for the pure vibrating screen type, it can be upgraded by installation of a crusher to realize the crushing and screening function. The frame carrying platform needs no additional investment and you can directly purchase the corresponding main engine equipment (cone crusher or vertical shaft impact crusher) and corresponding accessories to upgrade and expand the production scale of the stone production line.

In time of two-stage and three-stage medium and fine crushing, if the K-series portable crushing and screening plants are equipped with the CS, HST or HPT series cone crusher with high performance and high production capacity, we can achieve high productivity, large crushing ratio and excellent grain shape. The CS, HST or HPT series cone crushers are perfectly designed in crushing stroke, crushing speed and crushing chamber shape, which, as proved, has advantages in performance, efficiency, production capacity and product quality over the traditional cone crushers.

When medium and fine cone crushers are needed in the two-stage or three-stage portable crushing process, according to the crushing application requirements, there are several portable plants available for options, including nine types equipped with cone crushers and six types equipped with vertical shaft impact crushers; moreover, such portable plants are equipped with screening machines, able to classify materials or go into next-stage crushing.

The K-series medium and fine crushing and screening portable plants boast the maximum throughput of A + t/h. There are three kinds of pure vibrating screen types available. As for the pure vibrating screen type, it can be upgraded by installation of a crusher to realize the crushing and screening function. The frame carrying platform needs no additional investment and you can directly purchase the corresponding main engine equipment (cone crusher or vertical shaft impact crusher) and corresponding accessories to upgrade and expand the production scale of the stone production line.

mobile aggregate vibrating screen working principle

Main features of mobile aggregate vibrating screen

1.Large-throughput efficient single-cylinder cone crusher is newly equipped

2.Effective and reliable fine crushing main engine devices

3.From single application to multiple-in-one application

4.The vibrating screen is additionally provided with the function of installation angle adjustment to enable the complete 5.set to have more powerful processing capacity.

6.Adaptive main engine device switchover can meet customers' personalized needs.

7.Flexible parking function, quick access to the working mode

1.Large-throughput efficient single-cylinder cone crusher is newly equipped

2.Effective and reliable fine crushing main engine devices

3.From single application to multiple-in-one application

4.The vibrating screen is additionally provided with the function of installation angle adjustment to enable the complete 5.set to have more powerful processing capacity.

6.Adaptive main engine device switchover can meet customers' personalized needs.

7.Flexible parking function, quick access to the working mode

mobile aggregate vibrating screen parameters:

| Model | Specs. of screening equipment | Specs. of crushing equipment | Specs. of main belt conveyor | Max.feeding size (mm) | Transportation dimension(mm) |

| KC75-2 | 3Y1848 | CS75B | B800×7.5m | 150 | 12600×3000×4500 |

| KC160-2 | 3Y1860 | CS160B | B800×8.5m | 205 | 13800×3000×4500 |

| KT100-2 | 3Y1848 | HST100H1 | B800×7.5m | 185 | 12600×3000×4500 |

| KT160-2 | 3Y1860 | HST160H1 | B800×8.5m | 185 | 13800×3000×4500 |

| KT250-2 | 3Y1860 | HST250H1 | B800×8.5m | 215 | 13800×3000×4500 |

| KH300-2 | 3Y1860 | HPT300C2 | B800×8.5m | 210 | 13800×3000×4500 |

| KF1214-2 | 3Y1860 | PFW1214 | B800×8.5m | 250 | 13800×3000×4500 |

| KF1315-2 | 3Y2160 | PFW1315 | B1000×8.5m | 300 | 13800×3150×4500 |

| KF1318-2 | 3Y2160 | PFW1318 | B1000×8.5m | 300 | 13800×3150×4500 |

| KS1848-1 | 3Y1848 | -- | B800×7.5m | -- | 12590×3000×4500 |

| KS1860-1 | 3Y1860 | -- | B800×8.5m | -- | 13800×3000×4500 |

| KS2160-1 | 3Y2160 | -- | B1000×8.5m | -- | 13800×3000×4200 |